By: Nathan Prisco, DOE Advanced Manufacturing Office Arctic Innovator Fellow at the University of Alaska Fairbanks

Editor's Introduction: To encourage innovation in the Arctic, the US Department of Energy (DOE) founded the Arctic Advanced Manufacturing Innovator Program in 2019. The program is designed for early career professionals with fresh ideas and innovative approaches to address fundamental hard technology manufacturing challenges. Arctic Innovator Fellows are sponsored for two years to split their time between UAF, a national lab, and DOE's recently reestablished Arctic Energy Office as they develop their technologies and pursue commercialization. Nathan Prisco, the program's first Innovator Fellow, shares his experience here.

Arctic Innovator Fellows pursue technology projects in the Alaskan ecosystem that have potential for broad global impacts. I am pursuing two technology projects that I believe meet these criteria: Establishing a low carbon ammonia fuel supply chain originating in the Alaskan Arctic; and Compact, low-waste systems for distributed polymer manufacturing. Through Alaska's Foundational I-Corps Program, I've met with potential partners, customers, suppliers, distributors, and investors to identify possible paths to market for my early-stage manufacturing concepts. These experiences have opened my eyes to the significant role that the Arctic region will occupy in the coming decades in terms of technological innovation, economic growth, and climate leadership.

Establishing a Low Carbon Ammonia Fuel Supply Chain Originating in the Alaskan Arctic

The International Maritime Organization's 2020 low-sulfur mandate required a switch to cleaner fuels in the shipping industry. In the short term, this demand can largely be met, but future regulations will favor fuel-switching to either liquefied natural gas (LNG) or alternatives. Ammonia, an indirect hydrogen storage media containing a high content of hydrogen, has emerged as a top contender because it is cost-competitive, sulfur-free, and is a zero-carbon fuel liquid. The International Energy Agency's Global Energy Consumption and CO2 Emissions in International Shipping in the Sustainable Development Scenario, 2019–2070, published in 2020, projects that ammonia will satisfy 10%, 25%, and 70% of all maritime fuel demand in 2040, 2050, and 2070, respectively.

Last October, Japan's Ministry of Economy, Trade, and Industry established an industry council assigned with the task of forming international partnerships to begin importing ammonia fuel for use in electricity production starting in the late 2020's. Initially, Japan is relying on using natural gas as the input with carbon capture and sequestration to produce decarbonized ammonia, this is viewed as the lowest cost implementation strategy. (see: Japan Strikes First Fuel Ammonia Cooperation Deal with Abu Dhabi's ADNOC). Over time, it is expected that there will be a shift to producing ammonia from air and water using renewable energy.

In January 2021, the DOE Office of Fossil Energy announced plans to make $160 million in federal funding available to "help recalibrate the nation's vast fossil fuel and power infrastructure for decarbonized energy and commodity production." Much of this is focused on technologies to support a hydrogen economy; however, some believe ammonia will be an important hydrogen carrier over great distances. This includes US company, Air Products, which is involved in a five billion dollar joint-venture to produce ammonia in Neom, Saudi Arabia and safely deliver it to Europe for distribution and use in hydrogen vehicle refueling stations (see: World's Largest Green Hydrogen Project Unveiled in Saudi Arabia).

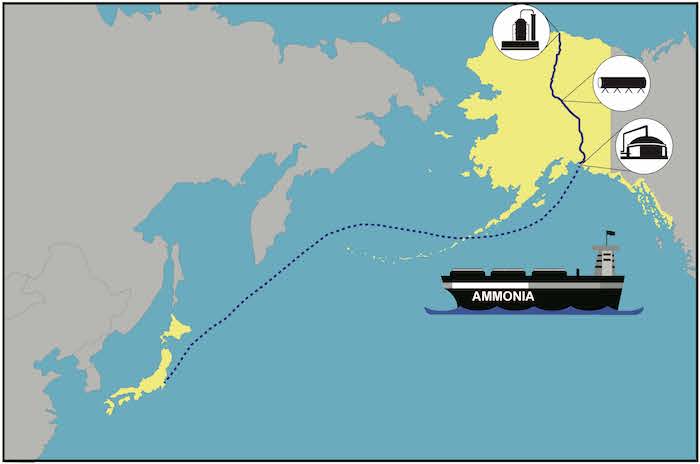

Over the years, as oil producers in Alaska sought to increase output, they expanded the capacity of their gas handling facilities. At the Prudhoe Bay site alone, 280,000 barrels per day of (BPD) oil are produced in addition to 1,500,000 BPD water and nine billion standard cubic feet (BFSCD) of gas, which are reinjected into the reservoir (Fisk 2020). The existing gas injection facilities and pipeline infrastructure could support low-carbon hydrogen or ammonia production at an unprecedented scale. Given Alaska's abundant renewable and fossil resources, geographic proximity to important shipping routes, and underutilized infrastructure, the state has the potential to occupy a leading role in carbon-neutral hydrogen or ammonia supply chains (Figure 1).

My partner institution, the Pacific Northwest National Laboratory, has broad capabilities in renewable and fossil energy, sub-surface engineering, marine sciences, environmental remediation, and materials science. Currently, I am working with Dr. Carlos Fernandez and a team of researchers to evaluate the transport of ammonia and crude oil blends through the Trans-Alaska Pipeline System (TAPS). I plan to use the resulting technology and engineering data to support ongoing venture and project development efforts.

Compact, Low-waste Systems for Distributed Polymer Manufacturing

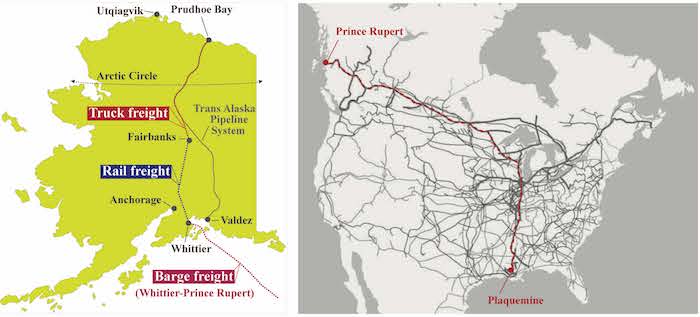

Even as there is a transition to alternative fuels, there will be new opportunities for carbon avoidance and energy efficiency gains in fossil resource production on the North Slope. For instance, to reduce water usage in oil production, a dilute polymer thickening agent can be used. This solution is currently being validated at the DOE Alaska North Slope Field Laboratory with encouraging results. But where the polymer comes from can make a big difference in carbon footprint, and to Alaska's economy. Delivery to the Alaskan Arctic from centralized industrial centers on the US Gulf Coast adds significant costs and carbon transportation emissions on all delivered products as shown for polymer in Figure 2. There are potential environmental and cost benefits to manufacturing locally, and smaller scale projects motivate process innovation.

During the I-Corps process, I met JR Wilcox, CEO at Alyeschem, LLC who is developing a North Slope modular methanol plant that can meet demand in the state, and which may help support future polymer production. We are working with faculty at the University of Alaska Fairbanks and the University of Arkansas Fayetteville on compact, low-waste membrane and gas separation technologies to support distributed polymer manufacturing. If successful, this would be a big cost-saver for the North Slope and would de-risk future projects, including decarbonized hydrogen or ammonia production.

To learn more about the frontiers of distributed energy innovations check out the Alaska Center for Energy and Power (ACEP) website.

About the Author

Nathan Prisco has a PhD in Chemical Engineering from the University of California Santa Barbara and a BS in Chemical Engineering from the University of Texas at Austin. He formerly worked for LP Amina in Beijing, China on pollution reduction and beneficiation processes for the coal power industry. His favorite Alaska experience was snowshoeing 10 miles to Tolovana Hot Springs in minus 10 to 15 °F weather. His current interests are in responsible natural gas utilization to promote sustainable development and to democratize chemical production.

Nathan Prisco has a PhD in Chemical Engineering from the University of California Santa Barbara and a BS in Chemical Engineering from the University of Texas at Austin. He formerly worked for LP Amina in Beijing, China on pollution reduction and beneficiation processes for the coal power industry. His favorite Alaska experience was snowshoeing 10 miles to Tolovana Hot Springs in minus 10 to 15 °F weather. His current interests are in responsible natural gas utilization to promote sustainable development and to democratize chemical production.

References

Fisk, J. 2020. Today's Prudhoe Bay, presentation at 41st Annual Alaska Resources Conference. https://www.akrdc.org/conference.